Septiox®: A Proven Solution for Septicity in Wastewater Treatment

Introduction

Septicity is a persistent challenge in wastewater facilities, where oxygen-deficient conditions allow sulphate reducing bacteria to generate Hydrogen Sulphides (H₂S). This toxic and corrosive gas drives a range of problems from odour complaints to infrastructure damage and higher operational costs.

This paper explores the causes and impacts of septicity and introduces Septiox®, Chemifloc’s dual-action Ferric/Sodium Nitrate solution. With both preventative and corrective treatment mechanisms, Septiox® delivers reliable odour control, infrastructure protection, and cost efficiency.

Finally, a case study, demonstrating practical application is presented to show how Septiox® is successfully applied in practice at a wastewater facility in Co. Cork, Ireland.

What is septicity?

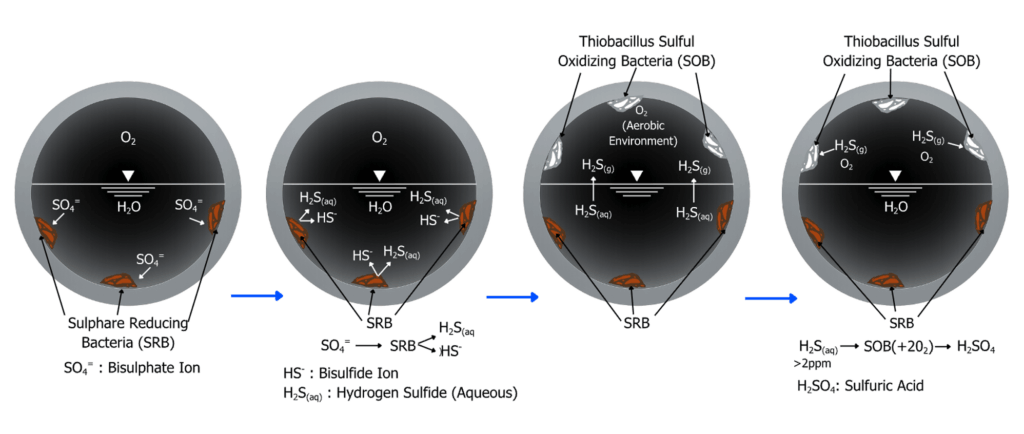

Septicity can arise due to the biological decomposition of organic matter containing sulphur or from the reduction of sulphur compounds in wastewater in the absence of free oxygen. In such conditions, the decomposition activity of sulphate-reducing bacterium (SRB) in sewer systems will produce Hydrogen Sulphide (H₂S), a toxic and odorous gas.

Causes

Septicity primarily arises from a lack of oxygen combined with the presence of organic matter in wastewater.

Conditions such as stagnant flow, poor mixing, and insufficient aeration create an environment in which SRBs thrive. Visible signs of these conditions include slime layers on pipe walls and accumulations of sludge or silt at the base of the pipe.

Consequences

Increased concentrations of H₂S, an extremely hazardous gas with a low odour threshold of less than 10 ppb, can have serious negative effects. Exposure to concentrations around 300 ppm can lead to sudden unconsciousness and even death. H₂S contributes to several issues, including unpleasant odours, health hazards and worker safety concerns.

As well as health risks, H₂S can lead to operational challenges. When oxidized, H₂S forms Sulphuric Acid (H₂SO₄), which aggressively corrodes pipes and concrete structures. These combined effects not only increase maintenance costs but also reduce the overall efficiency and reliability of wastewater treatment plants.

Septiox® as a solution

Chemifloc, a CSG Company, has developed Septiox® to treat septicity. Septiox® is a Ferric Nitrate/Sodium Nitrate blend combining two complementary treatment mechanisms to manage H₂S effectively.

Biological oxidation: The Sodium Nitrate in Septiox® encourages denitrifying bacteria to outcompete sulphate-reducing bacteria, therefore preventing the formation of H₂S.

Chemical precipitation: The Ferric Nitrate in Septiox® reacts with dissolved H₂S to form insoluble Iron Sulphide.

With its dual action, Septiox® prevents H₂S formation as well as removing any H₂S already present in the system. This ensures rapid odour control and compliance with relevant safety regulations. In addition to being non- corrosive to pipework and helping preserve infrastructure, Septiox® also enhances the coagulation process by introducing iron into the system.

Cost benefit analysis

Compared to other treatments, Septiox® offers similar cost levels, but has significant operational advantages.

It is easy to dose, requiring only one product to eliminate existing H₂S and inhibit the formation of new H₂S. Septiox® quickly brings the wastewater into a steady state, reducing variability in the system. In contrast, other products often require complex dosing routines at multiple locations, increasing the running costs and the carbon footprint of the plant.

While Ferric Chloride can be used to remove H₂S and is comparable in price, Chloride is highly corrosive to metals and concrete, making it less suitable for long term infrastructure protection and in older networks.

Conclusion

By combining biological and chemical mechanisms, Septiox® delivers rapid and sustained control of H₂S in wastewater systems, reducing odour, corrosion, and safety risks. The case study presented also highlights its proven performance in challenging conditions, with clear benefits for operators and infrastructure alike.

Field data continues to validate the effectiveness of Septiox®, which consistently delivers rapid and sustained reductions in H₂S across wastewater networks. By combining nitrate driven biological suppression with ferric-based chemical precipitation, Septiox® both prevents and removes H₂S. This dual-action chemistry provides superior protection against odour, corrosion, and variability compared with conventional single-mechanism treatments.

Dr Ed Roycroft, Chief Science Officer, CSG

We understand that every wastewater network is unique. Our scientists and engineers are available to discuss how Septiox® can be applied to optimise performance in your facility. Get in touch to arrange a technical consultation

Septiox® Case Study

Background

Septiox® is a well-established product that has been used in the Irish water network for many years. At Ballinure Pumping Station(PS), Co. Cork, Ireland, 80,000 m³ of municipal effluent is pumped daily through a 10 km pipeline with a diameter of 1.8 meters to Carrigrennan WWTP (Wastewater Treatment Plant), Little Island, Co. Cork.

Due to the relatively low flow rate (<1 m³/s),the system provides favourable conditions for H₂S formation. This makes it an ideal setting to demonstrate the effectiveness of Septiox® in preventing H₂S generation and improving the overall efficiency of the wastewater treatment process.

Dual action approach

Chemifloc installed a dosing system at Ballinure PS and a H₂S detector was placed at the end of the pipeline in Carrigrennan WWTP. Septiox® was applied to the system with a dose rate of 50 mg/L and a daily dosing of 4 tonnes. The Ferric Ion in Septiox® reacts with any dissolved H₂S formed in the supply pipeline to form insoluble FeS and the Nitrate in Septiox® suppresses H₂S formation.

Results

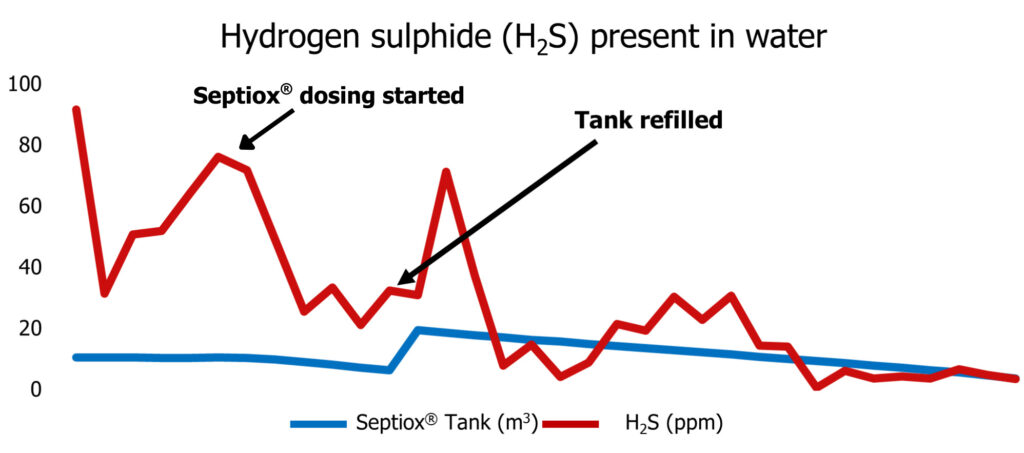

- In less than 48 hours, H₂S levels were reduced by over 70%, until the system reached 2 equilibrium.

- After 10 days of dosing, H₂S levels were reduced by more than 98%, as shown in Figure 1 below.

Figure 1: Rapid reduction in H₂S levels at Ballinure PS following Septiox® dosing

Conclusion

The case study demonstrates how Septiox® rapidly and effectively controls H₂S in challenging wastewater environments, reducing odour, protecting infrastructure, and improving process efficiency. In addition, Septiox® enhances worker safety, supports regulatory compliance, and simplifies operations by replacing the need for multiple products. With fewer dosing points and reduced handling requirements, it also lowers the overall carbon footprint of treatment, delivering both performance and sustainability benefits.